Growing Extra-long Staple Cotton by Vertical Hydroponic Cultivation Cotton is a popular material in textiles production. The longer the cotton fibres, the softer, stronger and finer the yarns and fabrics made. Egyptian cotton and pima cotton, whose fibres are longer than standard cotton, are classified as extra-long staple (ELS) cotton. These ELS cotton are ideal for textiles products of high smoothness and good hand feel. ELS cotton needs hot days and cool nights for growing. The specific climatic conditions limit the areas for its cultivation which leading to ELS accounting for only 3% of global cotton production. In order to overcome such limitations, this project has developed an indoor vertical hydroponics approach to cultivate ELS cotton. Hydroponics: A Sustainable Solution for Saving Fertiliser and Water Hydroponics, unaffected by weather conditions, has become a popular farming method in recent years. Installing the hydroponics system in a vertical farming set-up can fully utilise urban spaces such as warehouses or industrial buildings. Currently, hydroponics is mostly used to grow vegetables and there is yet to be thorough studies on how to use vertical hydroponics to grow ELS cotton. The research project began by studying the feasibility of growing ELS cotton indoors and found out the optimal growing conditions such as temperature, humidity, lighting, fertiliser and carbon dioxide concentration. As a result, the research team successfully grew ELS cotton in a vertical hydroponics system set up locally. The fibre length, strength, elongation and fineness of the ELS cotton in the study are similar to the current ELS cotton with a 50% increase of yield compared to those in soil-based farming. The hydroponics save around 90% of water compared to soil-based farming since the irrigation water can be recirculated and reused. In addition, hydroponic cotton can absorb nutrition directly through its roots with no leaching, reduce the use of fertiliser by about 75%, and reduce pesticide application to zero. Innovative System to Monitor Cotton Growth The setup of hydroponics contains sensors, LED lighting devices, exhaust fans, temperature and humidity regulating devices and water pumps. By removing the climatic restrictions on where ELS cotton can be grown, this vertical hydroponic system can be installed anywhere. Setting up the system near a textile mill, for instance, can shorten the cotton supply chains, thereby reducing transportation costs and carbon emissions. The system can also be driven by renewable energy. It uses solar energy with only the installation of a few solar panels to meet its operation needs, thereby reducing the energy consumption. The vertical farming method increases the yield per unit area. In this project, 50 ELS cotton plants were grown and a total of 6 pounds of cotton fibre in a life cycle were produced. This is about twice the crop yield in the United States and Egypt. It is estimated that the production cost of each pound of hydroponic cotton fibres is as low as 1 euro. Its breakthrough garnered the project a silver award in the Special Edition 2022 Inventions Geneva Evaluation Days.

|

The ELS cotton grown in an indoor vertical hydroponic farm

The ELS cotton grown in an indoor vertical hydroponic farm

Optimum conditions for the growth of ELS cotton in indoor hydroponics

farm are found

Optimum conditions for the growth of ELS cotton in indoor hydroponics

farm are found

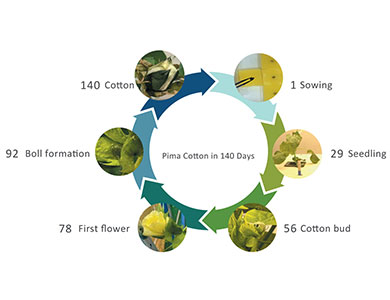

It takes 140 days to grow ELS cotton with vertical hydroponics

It takes 140 days to grow ELS cotton with vertical hydroponics

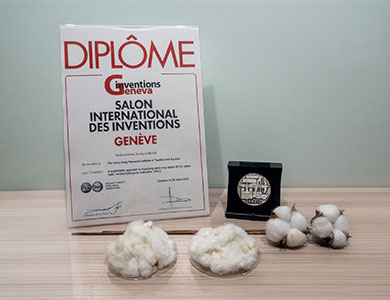

The project receives a Silver Medal (agriculture) in the Special Edition

2022 Inventions Geneva Evaluation Days

The project receives a Silver Medal (agriculture) in the Special Edition

2022 Inventions Geneva Evaluation Days