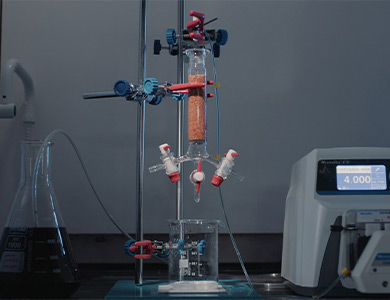

Dye Removal from Denim Textile Wastewater by a Combinative Adsorption and Regeneration System Denim textile wastewater contains dyes and chemicals that pose health and environmental risks. Adsorption of dyes using activated carbon is a common treatment method but spent adsorbent has to be disposed once it is saturated with dyes, generating solid waste. This project develops an in-situ physiochemical approach that combines adsorption and regeneration of dyes. First, the dye wastewater is poured into a specially designed apparatus filled with metal-doped alumina as the adsorbent. Alumina is a positively charged adsorbent that traps the commonly used dyes in denim production, such as indigo blue and sulphur black, which are negatively charged. This process turns the wastewater into a clear and colourless solution. Once the adsorbents become saturated, ozonated water is introduced in an upflow manner. The metal oxide that catalyses on the adsorbent surface facilitates the generation of hydroxyl radicals in the ozonated water. These radicals break the molecular bonds of the dye molecules on the adsorbent, converting them to simpler and harmless substances like water and carbon dioxide. The adsorbent is regenerated and returns to resembling its original brown colour, ready for another cycle. This alumina adsorbent has a saturated time of over 60 continuous hours. Additionally, this approach maintains over 90% adsorption capacity after 10 adsorption-regeneration cycles, ensuring long-lasting effectiveness. Its outstanding reusability minimises the disposal of spent adsorbent and decomposing dyes into simpler molecules eliminates toxic air emissions. The treated water meets the necessary professional standards for reuse in denim production, contributing to water reuse and reduced water consumption in the plant. Compared to treatment like ultrafiltration, this approach is only a quarter of the cost to remove one ton of dye wastewater. This project has garnered a Gold Medal in the International Exhibition of Inventions Geneva this April for its innovative, eco-friendly and low-cost treatment for denim textile wastewater, fostering a more sustainable development of the textile industry.

|

This in-situ physiochemical approach combines dye adsorption and

adsorbent regeneration

This in-situ physiochemical approach combines dye adsorption and

adsorbent regeneration

The adsorbents return to resembling their original brown colour after

regeneration

The adsorbents return to resembling their original brown colour after

regeneration