Dye Removal from Denim Textile Wastewater by a Combinative Adsorption and Regeneration System

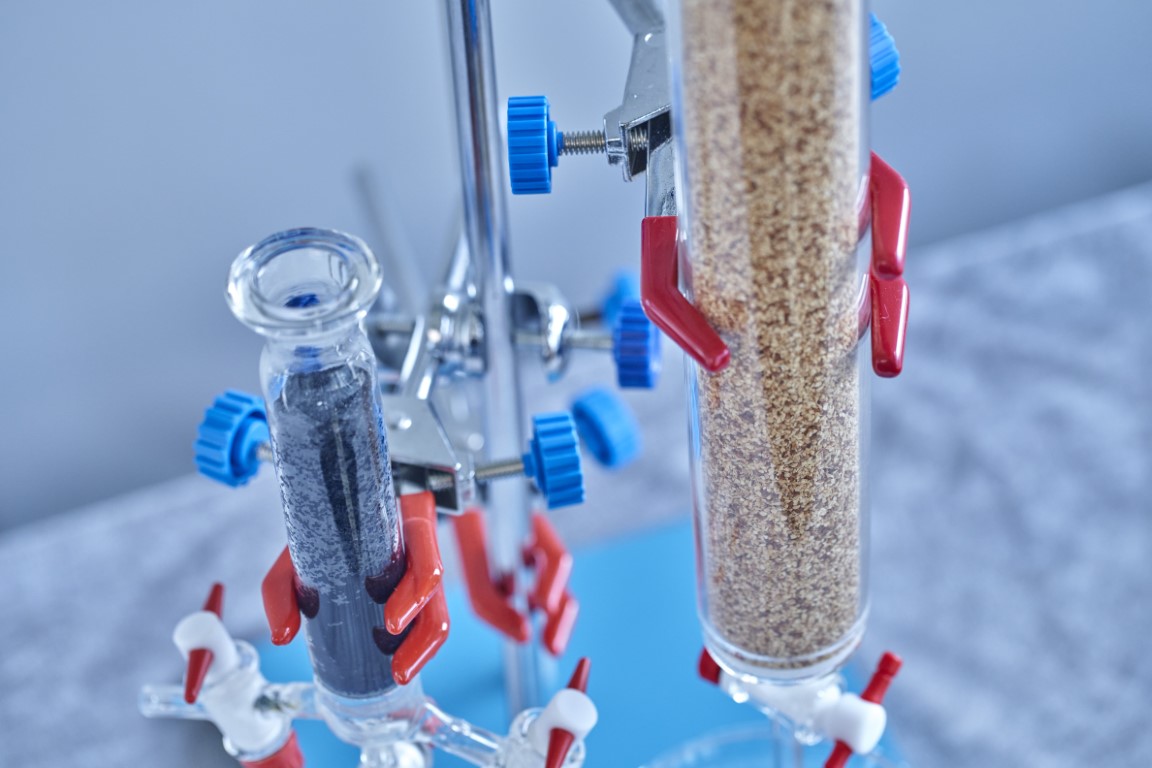

This project adopts an integrative approach to remove indigo dye from textile wastewater. It combines the process of dye adsorption and adsorbent regeneration. The system uses alumina-based adsorbents as efficient dye adsorbent materials. Once the adsorbent material is saturated, it is regenerated through ozonation for reuse.

Indigo dye plays a significant role in denim production but the use of indigo dye in denim production can have environmental implications. Wastewater generated during denim fabric dyeing can pollute water if not properly treated. This combinative process improves water quality and reduces adsorbent solid waste and cost, making it an environmental-friendly and cost-effective indigo dye treatment method.

Dye removal and wastewater treatment technology for denim production and other processes that generate dyed effluent.

- Waste reduction: the adsorbent has long service life of over 60 hours and it is highly reusable. After 10 processing cycles, the adsorbent remains over 90% removal efficiency for reuse.

- Cost-competitive: USD 1.6/m3 compared with other conventional indigo dye treatment techniques (USD 1.6-6.2/m3), such as activated carbon

An innovative, combinative, and efficient dye removal system that achieves over 90% removal efficiency. It helps improve water quality through decolourisation (colourity <25 pcu and Chemical Oxygen Demand (COD) <25 mg/L according to standard FZ/T 01107-2011).