Compact Electro-adhesion Gripper for Fabric Handling

This project develops a fabric handling gripper using electro-adhesion for compact holding of soft and thin fabric without damaging the fabric. It aims to enhance automation level in garment manufacturing, which remains labour-intensive nowadays.

Electro-adhesive gripper is an ideal solution for fabric handling and manipulation. Fabric delivery occupies about 80% of total production time in garment making. Manual pick-up and delivery of fabrics are still common because of the limitation of existing fabric grippers. To accelerate automation in textile industry and to save production time, electro-adhesive gripper is introduced.

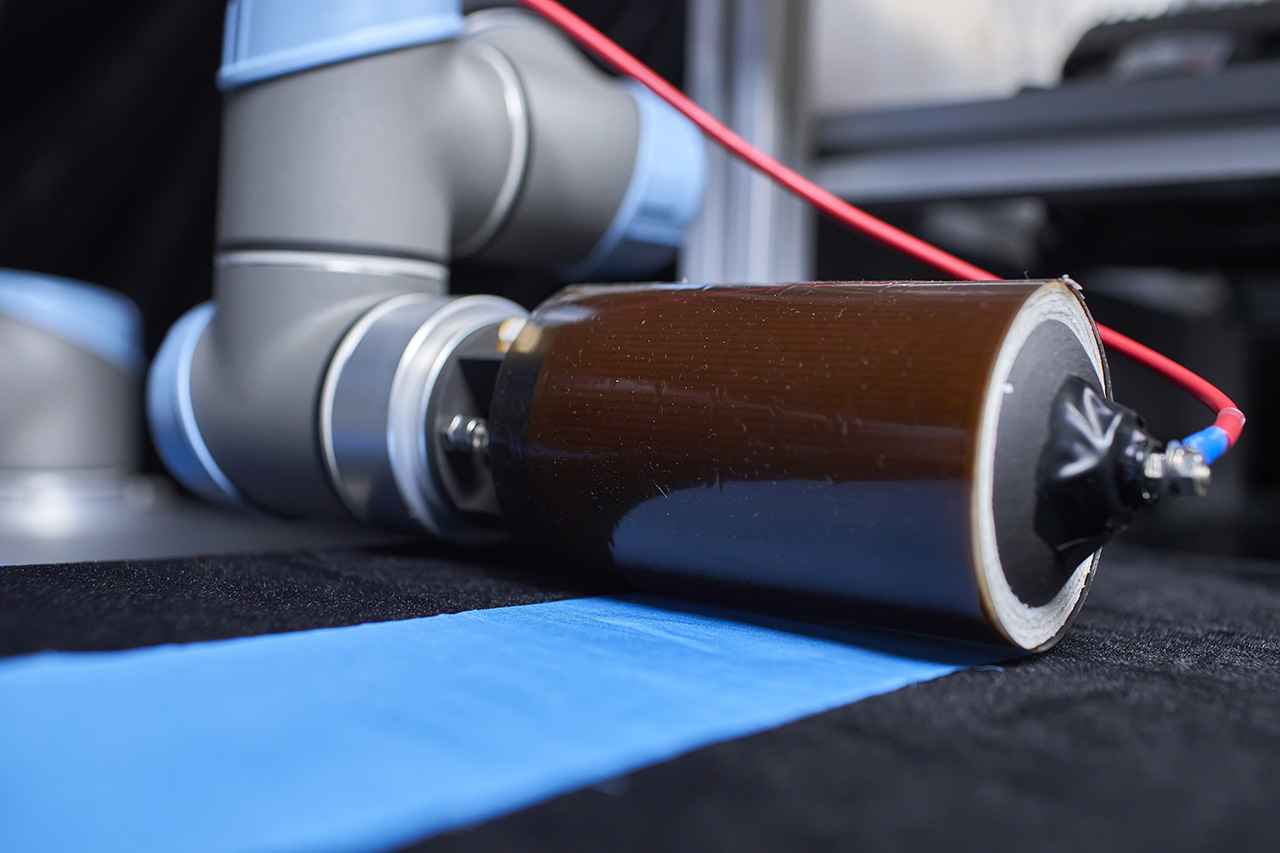

Robotic-armed controlled roller electro-adhesion grippers grasp the two edges of the fabric and transport it to the desired location of the downstream task. The gripper is equipped with an array of conductive electrodes installed on the roller surface. Using the principle of electro-adhesion, the charges induced on the gripper attracted the first layer of fabric from the ply.

Textile and clothing industry ranks low in terms of automation compared to other industries and production remains labour-intensive. To enhance automation level in garment manufacturing, using robotic-controlled gripper in fabric manipulation is a feasible solution. Among the existing fabric handling approaches, such as clamping, pinching, intrusive, gluing or cryo-freezing, our compact electro-adhesion gripper does not damage the fibre structure or leave folds on fabric surface. This innovation will help facilitate the textile industry heading towards Industry 4.0.

A smarter design of electro-adhesion gripper for flexible and efficient fabric manipulation

Flat plate gripper is a common type of electro-adhesion gripper for fabric handling. Both flat plate and roller grippers pick up fabric by applying electro-adhesion to attract the fabric. However, the flat plate type gripper cannot pick up a piece of fabric larger than the area of plate; this may limit the use of electro-adhesion gripper in different garment production processes.

On the other hand, there are less restriction for roller grippers in terms of fabric size and arrangement. By only grasping the two edges of the fabric, it can handle fabrics whose size is much bigger than the gripper. Furthermore, it does not require the pre-handled fabric to be placed neatly as a stack or spread flat. Throughout the delivery, the fabric edges are firmly held while the fabric is kept flat and neat.

2024 Just Style Excellence Awards - Category Award Winner - Innovation (Fabric Handling Devices)

Development of Robust Electrostatic Gripper for Fabric Manipulation in Manufacturing

ITP/066/22TP

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.