Quick Response Quality Management (QRQM)

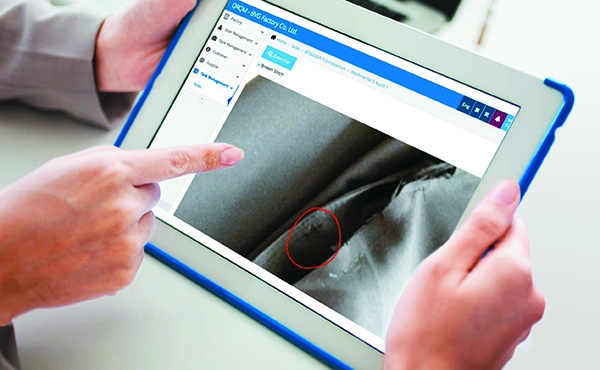

This research project proposes to develop a cloud-service platform, and making use of network connected tablet devices that have intuitive touch interface to capture, highlight, and upload product defects information for analysis and management. It offers a digital solution for the current apparel supply chain, which lacks management platform to categorize, and digitize product defects information efficiently. This system also develops an integrative way to analysis and report system and product quality problems for management to review, such that product quality knowledge can be retained despite of the high turnover rate of quality control staff.

This platform is highly scalable and applicable to garment manufacturers with one to hundreds of production lines. The quality management audit function is also suitable for the industrial engineering department to conduct workplace quality and safety audit.

The platform provides real time quality monitoring and alerts for garment factories. It is particularly suitable for SME garment manufacturers because the setup cost and hardware investment are low (e.g. monthly subscription from IT service provider), and the system is highly customisable for various garment production configurations. The proactive approach of quality management enables the factory to visualise quality problem in real time.

For larger scale garment manufacturers with multiple off-shore locations, this platform can help their headquarters to monitor the quality performance of all production lines in real time. Systematic quality problem can be resolved immediately and the platform avoids any shipment delay.

By making use of the latest mobile computing, cloud-based computing and telecommunication technologies, this platform provides real-time quality analysis and alert system for quality managers to proactively resolve quality problems. Quality manager can receive email or SMS alerts when systematic quality issues are captured by the QRQM platform. The quality prediction function also helps garment factory forecast potential quality defects, so that they can have a better production planning to minimise quality problem.

The user interface of the apps on the tablet devices is customised for garment factory quality control process. The user-friendly interface (e.g. gesture control for product defects categorisation) enables the front-line quality control staff to digitise product defects records in a few seconds.

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.