Separation and Recovery of Nylon from Textile Waste

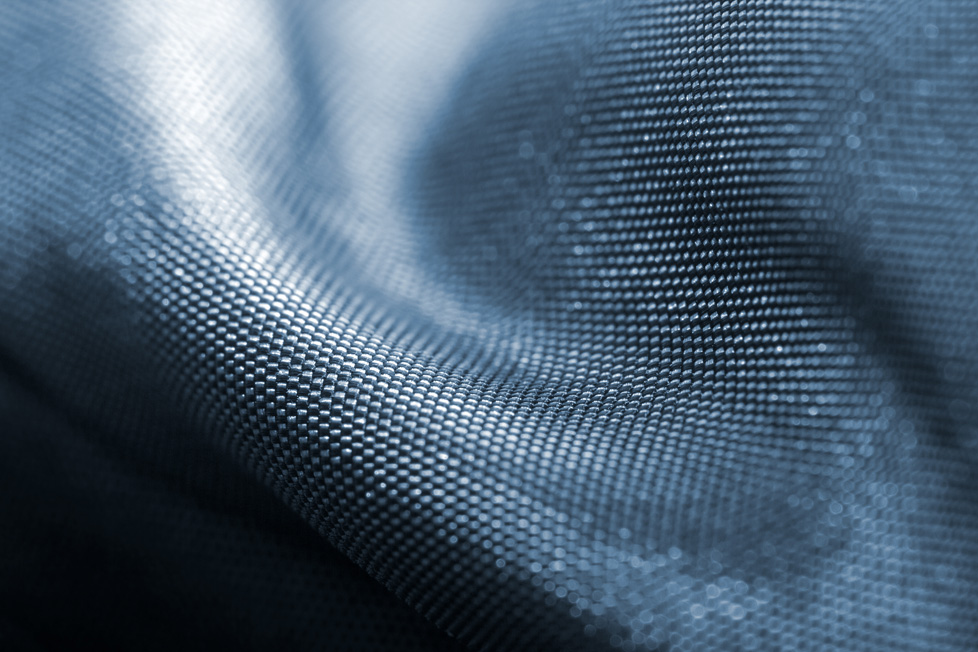

This project develops a lab-scale process to selectively separate and recover different nylon from textile waste and re-spinning of the recovered nylon for textile applications, using a low-cost and innovative method.

Nylon, a synthetic polyamide, has been widely used in different applications including clothing, reinforcement materials, moulded parts and packaging since its appearance in 1930s. This petroleum-based thermoplastic has made up 5% of the global fibre market share in 2020. The production of this second most used synthetic fibre has increased from 3.74 million tonnes in 1990 to 5.4 million tonnes in 2020. In view of the increasing textile waste and the demand to recover this high value material, this project explores a solution to develop selective process for separation and recovery of nylon from textile waste.

Separating and recovering nylon offers an alternative to virgin nylon fibre and a new recycling method of post-consumer garment made of nylon.

The new development to separate and recover nylon would raise the recycling rate of nylon, which is as low as 1.9% in the recycling market due to technical challenges and low cost for producing new nylon.

Currently, there is no commercial solution to address the separation and regeneration of nylon at a low-cost and eco-friendly level. Existing process often utilise strong chemicals and energy without selectively separate nylon from the collected waste.

The focus of this project covers the separation and regeneration of nylon from textile waste, while existing nylon recycling process mainly focuses no selectively recycling, depolymerisation nylon waste, then repolymerisation, and recycling fishing net.

2025 Just Style Excellence Awards - Category Winner - Environmental (Waste Reduction)

Separation and Recovery of Nylon from Textile Waste

ITP/008/22TP

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.