Waterless Solid State Decolourisation and Durability Treatment of Post-consumer / Recycled PET Fibres

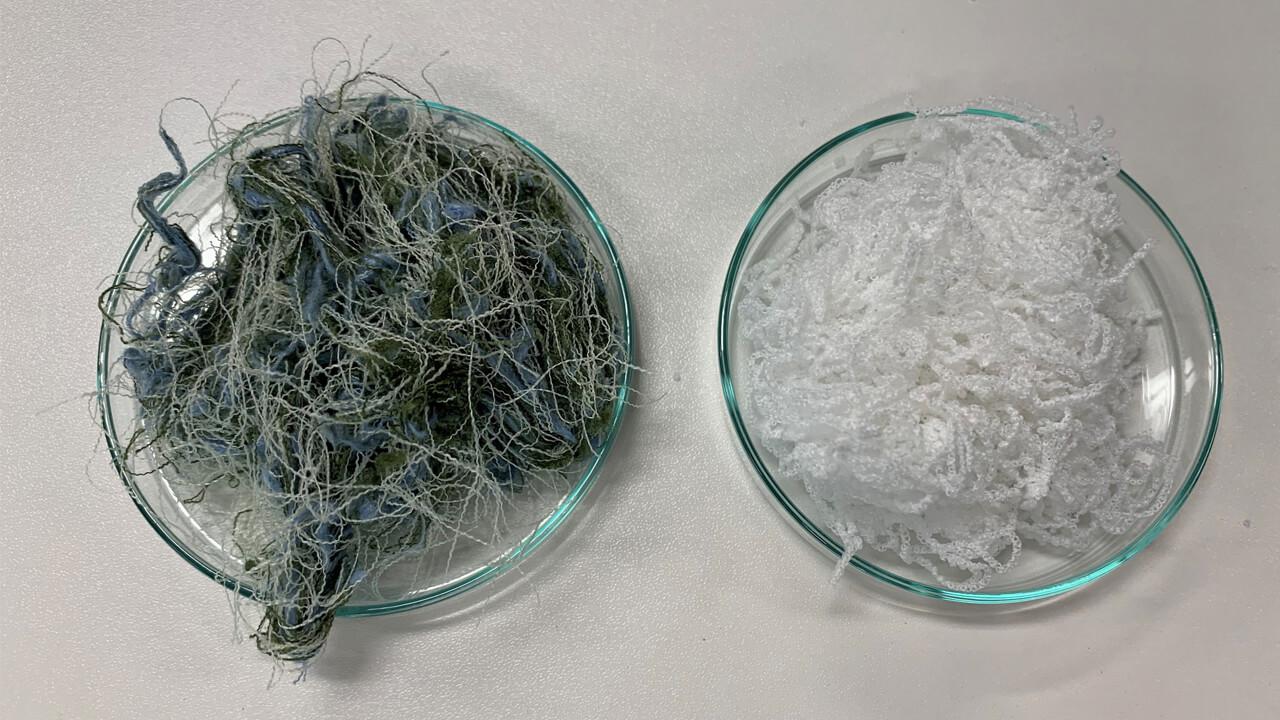

This chemical-free and waterless treatment method has been developed to improve the durability and longevity of post-consumer polyethylene terephthalate (PET) textiles. This technology enables PET textiles to be reused multiple times by conducting the process at 230oC for 8 hours, which results in a 200% increase in molecular weight and more than 98% decolourisation in a one-off. It allows PET fibres to be reused, recycled and redyed in a simple and inexpensive way by achieving decolourisation, molecular weight enhancement and durability improvement simultaneously in the textile treatment.

Using heat and vacuum method, the solid state polymerisation in improving molecular weight to recycled PET and PLA from used textiles takes around six hours to process. The physical properties of the treated fibres will be good enough for melt spinning and manufacturing of high value garment.

The proposed technology will be able to handle materials of varying forms and sizes, both particles and fibres, and in a wider application. It can potentially expand the applications of the recycled polymeric textile materials, bringing in more surprisingly useful benefits to the textile industry.

- The simple and low-cost process required to upgrade the properties of recovered PET and PLA materials proves to be a viable solution to meet the growing demand for recycled fibres in the clothing industry.

- The whole process is waterless and harmful chemicals free to regenerate post-consumer PET materials.

Solid State Polymerisation of PET and PLA for Properties Enhancement

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.