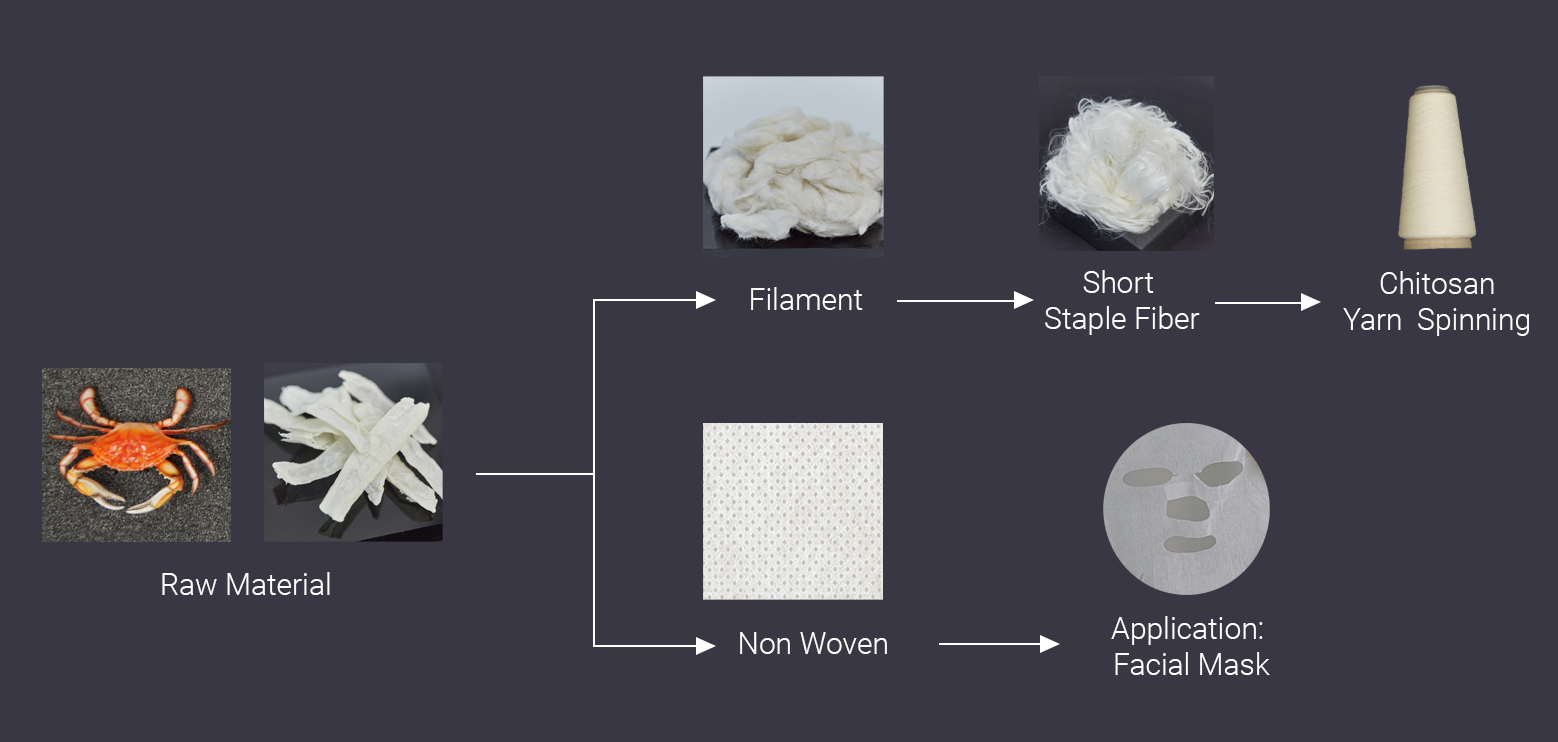

An Innovative Spinning System for Chitosan Yarn

• Hygiene and health care products;

• Textile and apparel products;

• Other potential areas of medical textiles that require a high standard of comfort and convenience.

• It solves the problems of roller-winding and as such greatly reduces wastage and production cost, while maintaining mechanical properties.

• The fibre derived from the new spinning system retains all the desirable biodegradable, biocompatible and antibacterial properties, which means it is the ideal fibre to use in areas such as wound healing.

• For manufacturers of medical apparel and health care products, the more reliable production of the yarn represents an opportunity to broaden the scope for new product development.

By upgrading the traditional spinning roller into a conductive one and optimizing the spinning parameters, this new spinning system not only solved the winding and wastage problem, but also improved the quality of chitosan yarn in terms of yarn strength and consistency.

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.