Sustainable Circular Coloration Technology for Eco-friendly Dyeing

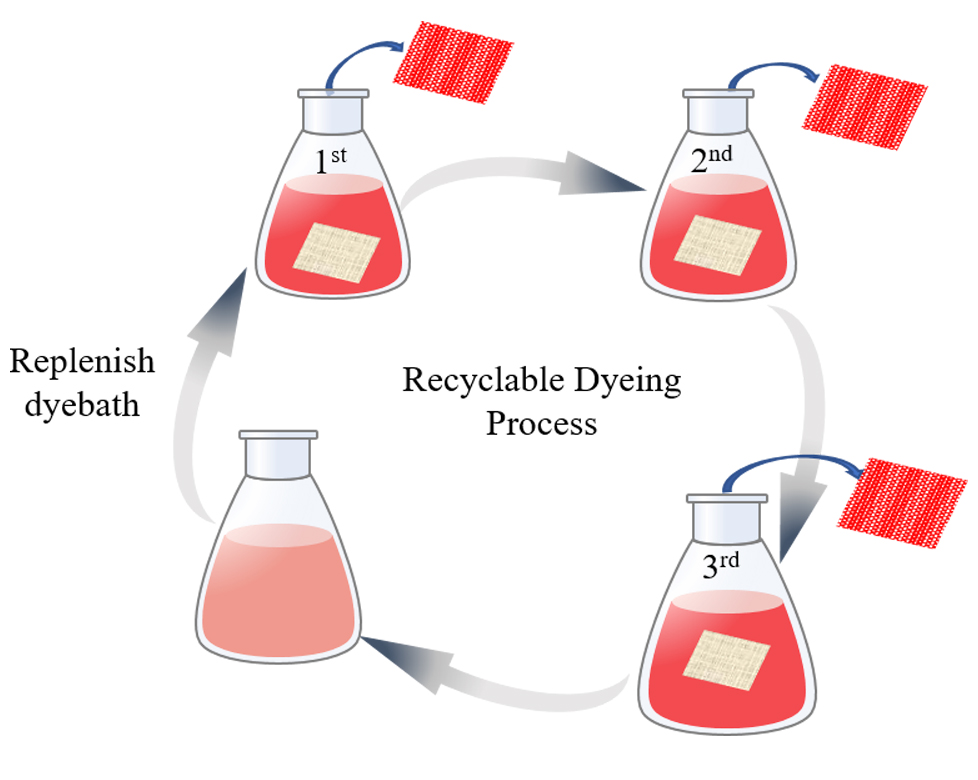

Sustainable Circular Coloration Technology promotes the reuse and recycling of dye water by adopting a new dyeing mechanism. Pre-treatment of fabric prior to dyeing allows the water in the dyebath to be reused for dyeing the next batches of fabric without discharging the dyeing water into river sources.

This technology aims to relieve environmental problems related to textile dyeing. The textile industry, especially textile dyeing, consumes a considerable amount of water, while treatment to used dyeing water is energy or chemical consuming. Despite of the tightened regulation on the treatment of textile dyeing water, illegal discharging is still not uncommon, and dyes may contain harmful substances that threaten the underwater ecosystem.

Process

- Fabric surface modification: developing a uniform coating of cationic polyelectrolyte on the surface of cotton fabrics

- Dyeing: the coating enables dyes to be adsorb on the fabric without adding mordent or other additives

- Reusing dyeing water: without adding any additives into the dye, the dyebath need not to be discharged and can be recycled for further dyeing

- Enhancing anti-bacteria and anti-virus property of dyed fabric

Sustainable Circular Coloration Technology is applicable in dyeing process to reduce discharge of dyeing water. With pre-dyeing treatment on fabric, this technology does not limit the type of dye to be used.

Reduce the use of harmful substances in dyeing water and water pollution

The discharged effluents generally contain loads of refractory unutilised dyes, inorganic salts, and multifarious additives such as penetrating agents, which make the dyeing effluents difficult to treat. These mordents may contaminate water sources and threaten marine lives and human health. Sustainable Circular Coloration Technology avoids the use of harmful substances throughout the dyeing process and it is an eco-friendly dyeing practice.

Reduce water footprint and energy consumption in the dyeing process

Textile industry is considered one of the most water-consuming industries. For instance, to produce 1 kg of cotton fibres, around 4,300 litres of water are used. Dyeing and finishing for the 1 kg cotton fibres consume approximately 125 litres of water. Once dyeing is completed, the dyeing water is discarded and a new batch of dyeing water has to be prepared. With Sustainable Circular Coloration Technology, the dyebath can be recycled and reused. Furthermore, as no treatment of decolourisation to dye water or filtering harmful substances are required, it can potentially save production time, cost, energy, and chemical.

Enhance fabric with durable anti-bacteria and anti-virus properties

Fabrics are hotbed for the growth and proliferation of microorganisms which may transmit diseases. The fabric dyed through the Sustainable Circular Coloration Technology is expected to achieve anti-bacteria and anti-virus standards.

To ensure fabrics are dyed properly, existing dyeing technology requires the use of mordent, inorganic salt or other additives to enhance dye uptake and colourfastness. Dyeing water containing additives have to be treated before discharging to water sources. Sustainable Circular Coloration Technology focuses on pre-dyeing cationisation of fabric which changes the dyeing mechanism, ensuring dyes are adsorbed on fabrics without using additives or mordent.

Development of Sustainable Circular Coloration Technology

ITP/032/22TP