Wearable Lithium-Ion Batteries Using Textile-Graphene Composite Electrodes

This project aims for developing a wearable type of Li-ion batteries using textile/graphene electrodes and solid electrolytes. Metallic textile/graphene composite electrodes will be used as lightweight, flexible, foldable, highly conductive, and high capacitance electrodes. Polyelectrolyte gels will be used as solid separator and electrolytes to provide good flexibility and leakage-free property. The device performance will be optimized to achieve good level of energy density but much better wearing properties, when compared with rigid type Li-ion batteries.

Wearable electronic technology will be the next big market opportunities after smartphones with increasing expected market revenue. Yet, it is still facing a bottleneck: the energy supply module should meet not only the power needs of these devices, but also wearable specifications (e.g., lightweight, flexible, foldable, safe). Unfortunately, current lithium-ion (Li-ion) batteries, the main choice of portable power source, are rigid, bulky, heavy, and use leakage-possible liquid electrolyte. The success of this project shall deliver a novel and versatile textile-based wearable battery technology, which will make a significant impact in a wide range of wearable electronic applications including display, energy harvesting, biomedical devices, GPS and fashion.

1) Intelligence electronic textiles (e.g., smart insoles/shoes/underwear, lighting garments/accessories)

2) Internet of Things (IoT) components (e.g., GPS sensors, logistic trackers)

3) Healthcare/medical accessories (e.g., pressure/temperature sensors)

The technology provides a new power supply solution for flexible and wearable electronics to significantly exploit the potential of their product designs. Wearable Li-ion batteries developed by textile/graphene composite electrodes and solid-state electrolyte can achieve excellent flexibility, safety while maintaining the good energy storage capability. They can be customised into any desirable sizes and shapes to make the most of the space in those electronic devices without compromising the its capacity and wearing comfort. In addition, the entire fabrication processes are compatible with the roll-to-roll production of textile fabrics and the manufacturing of batteries.

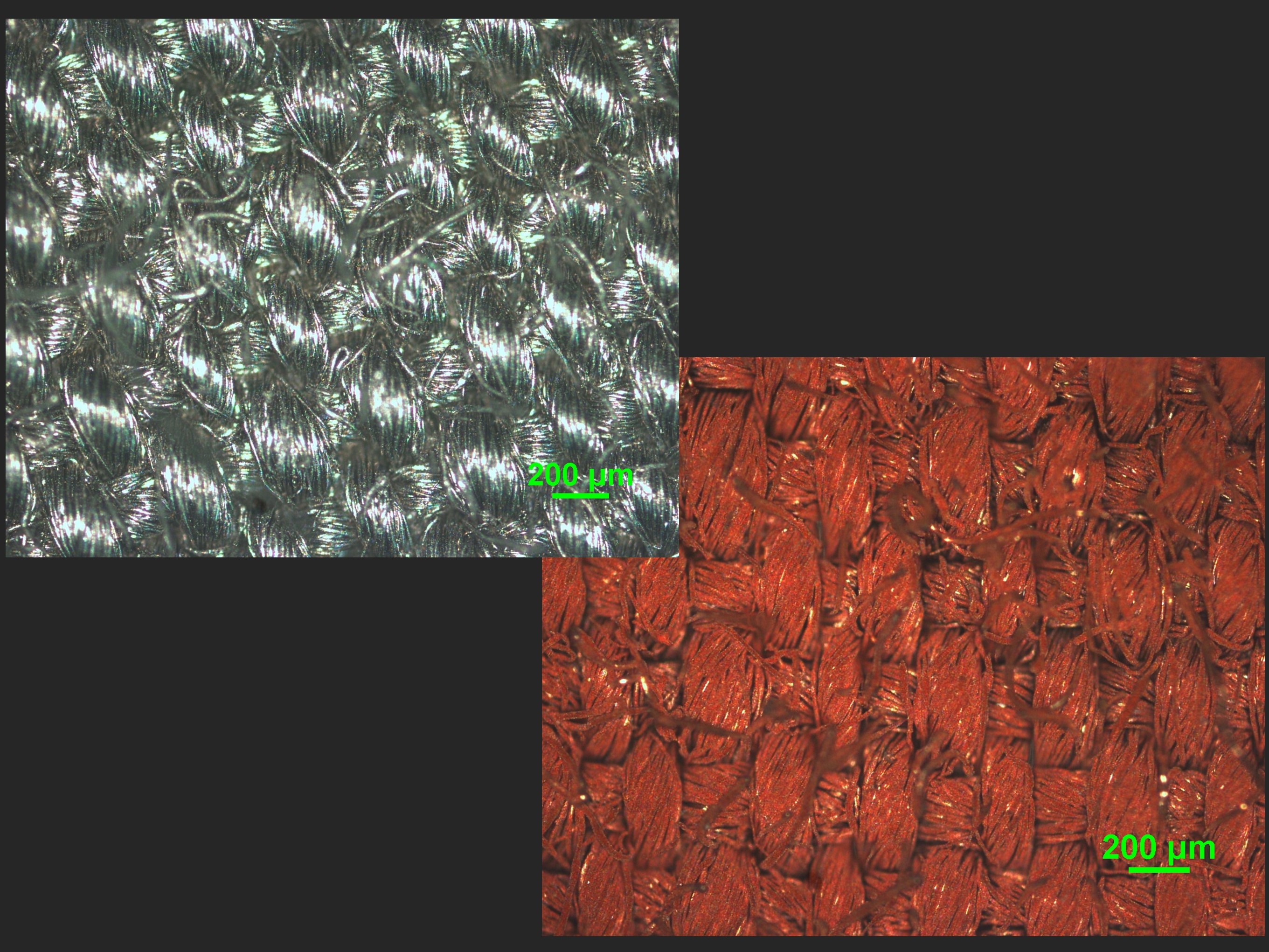

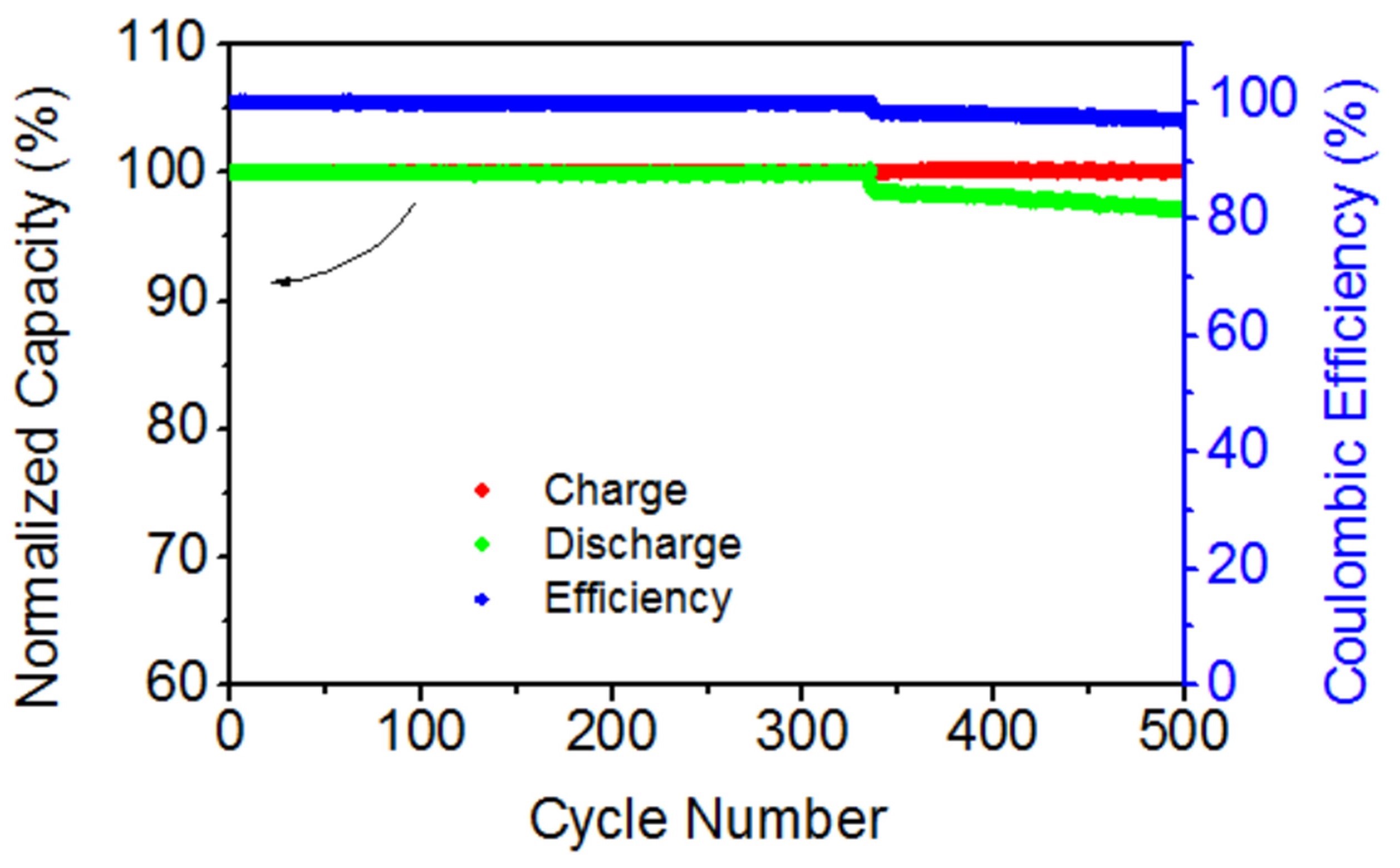

This technology replaces the metal thin-film with metallic textiles as the current collectors to assemble the wearable Li-ion batteries. Compared with the existing technologies (i.e., metal thin-film based Li-ion batteries), the metallic fabrics exhibits better mechanical flexibility and stability, therefore enabling the great foldability to the batteries. In additions, metallic fabrics with their fibrous structures provide sufficient surface area for the anchoring of composite materials, which greatly attribute to the good cyclic stability of the batteries.

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.