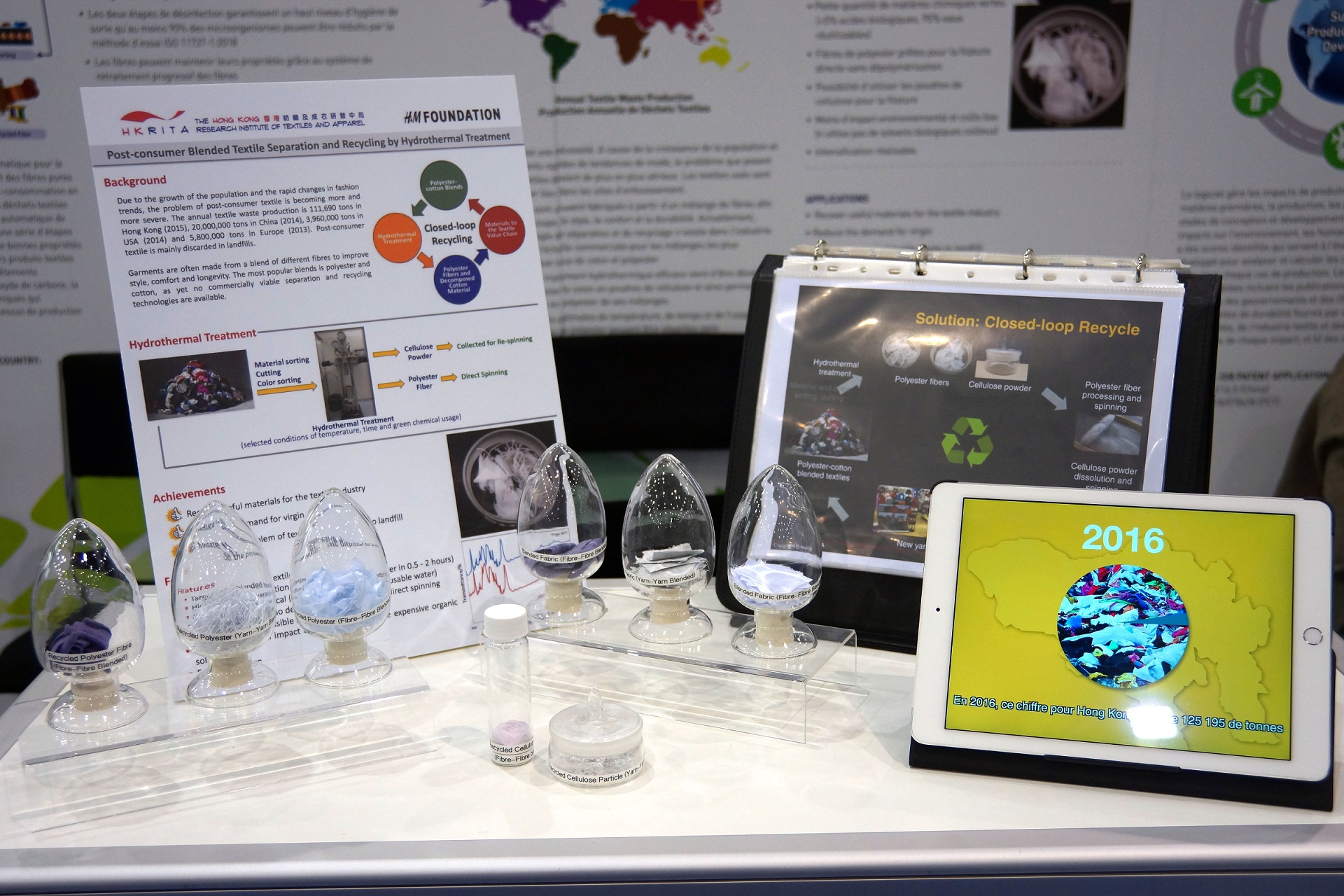

Green Machine: Post-consumer Blended Textile Separation and Recycling by Hydrothermal Treatment Phase 2

Green Machine is a polyester and cellulose recycling system by hydrothermal treatment and dissolution treatment on cotton and polyester blends. Through decomposing cotton into cellulose powders, it enables the separation of the polyester fibres from the blends. The quality of the polyester fibres is maintained, permitting fibre-to-fibre recycling. Recycled cotton cellulosic powder will be used in re-spinning and agriculture. Based on the research result of phase I development, this project aims to develop the Green Machine into a complete treatment process and an industrial set-up.

Through separation of the blended textile, Green Machine recovers PET fibre for re-spinning, while converts cotton fibre into cellulosic powder for a number of uses, including the re-producing of cellulose composite fibre, cellulosic water-retaining material for cotton farming (Absorboost), and PFC-free function durable water-repellent (DWR) surface finish, hence fulfilling the goal of “end-to-end recycling” where post-consumer textiles are recovered as the raw materials of the production cycle.

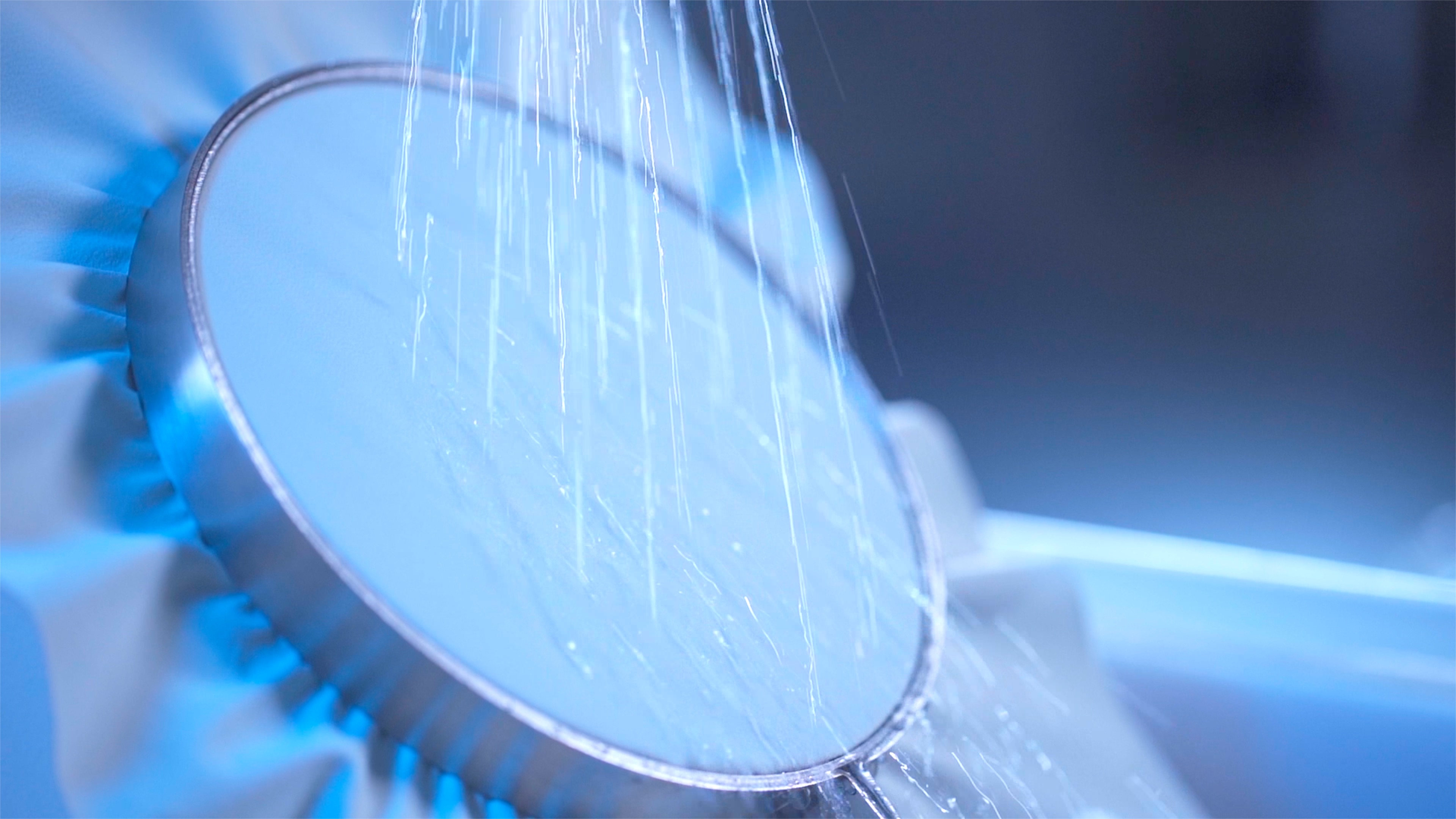

- The whole process uses only heat, water and a small amount of green chemical with a recovery rate of over 97% for polyester fibres in 2 hours.

- The technology of Green Machine has been applied in textile recycling and production. Monki, a fashion brand that focus on sustainability, is the first fashion brand to use textile materials made from the Green Machine in their collection. PT. Kahatex, an established textile manufacturer in Indonesia, has the first industrial scale system of the Green Machine operational there, with the processing capacity of 1.5 tons per day. While ISKOTM, one of the world’s leading denim producers, acquired a licensing agreement for Green Machine.

- Green Machine offers a commercially viable and complete blended-textile recycling solution and the system is easy to construct and operate.

- Compared to the 67 GJ required for producing every ton of virgin PET fibers*, the Green Machine uses only 19 GJ to recycle the same amount of separated PET fibers. It only requires 30% of the energy consumption to produce virgin PET fibers.

*Remark: Shen L., Nieuwlaar E., Worrell E. & Patel M. K. (2011). Life cycle energy and GHG emissions of PET recycling: change-oriented effects. The International Journal of Life Cycle Assessment, 16(6), 522-536.

The separated fibres with no depolymerisation are ready for spinning and manufacturing of new fabric, while the cellulose powders, decomposed from the cotton, can be applied to functional products such as super-absorbency materials and regenerated cellulose fibres.

ITMF Awards 2022

Edison Awards 2023 - Bronze Award

2023 World Changing Ideas Awards - Finalist

China Garment Industry Technological Progress and Contribution Awards 2023

China Patent Awards of Garment Industry 2023 - Silver Award

Reuters Events Responsible Business Awards 2023 - Finalist (Circular Transition)

Get in touch with us

If you have any enquiries or comments, feel free to contact us!

* Mandatory fields

Thank you for reaching out.

We will be in touch soon.